Whether ceramic capacitors are better than electrolytic capacitors depends on the specific application and the requirements of the circuit. Both types of capacitors have their own advantages and disadvantages, and the choice between them often comes down to factors such as capacitance value, voltage rating, size, cost, temperature stability, and other performance characteristics.

Ceramic Capacitors

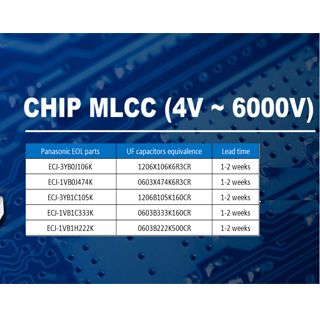

Ceramic capacitors are a type of electronic component used in a wide range of electronic circuits for their ability to store and release electrical energy. They are constructed using ceramic materials as the dielectric (insulating) material between two metal plates, which act as the capacitor’s electrodes. Ceramic capacitors come in various shapes and sizes, and they are known for their compactness, low cost, and versatility.

Here are some key features and characteristics of ceramic capacitors:

- Capacitance Range: Ceramic capacitors are available in a wide range of capacitance values, from picofarads (pF) to microfarads (µF), making them suitable for various applications.

- Size and Form Factors: They come in various form factors, including through-hole packages and surface-mount devices (SMDs). Surface-mount ceramic capacitors are popular in modern electronics due to their small size and compatibility with automated assembly processes.

- Voltage Rating: Ceramic capacitors are available in different voltage ratings, ranging from a few volts to several kilovolts, allowing them to be used in both low-voltage and high-voltage applications.

- Temperature Stability: Ceramic capacitors are generally more temperature-stable compared to other types of capacitors like electrolytic capacitors. This makes them suitable for applications where temperature fluctuations are a concern.

- Frequency Response: Ceramic capacitors have low equivalent series resistance (ESR) and equivalent series inductance (ESL), making them well-suited for high-frequency applications, such as in RF (radio frequency) circuits.

- Dielectric Types: There are different types of ceramic materials used as the dielectric in ceramic capacitors, including Class 1 (NP0, C0G) and Class 2 (X7R, Y5V). Class 1 ceramics offer high stability and low capacitance variation over temperature, while Class 2 ceramics provide higher capacitance values but with some variation over temperature.

- Dielectric Absorption: Some ceramic capacitors may exhibit a phenomenon called dielectric absorption or soakage, where the capacitor retains a charge even after being discharged. This behavior might impact certain applications.

- Non-Ideal Characteristics: Depending on the dielectric material and construction, some ceramic capacitors can exhibit piezoelectric and ferroelectric effects, causing voltage-dependent capacitance changes and nonlinear behavior in response to mechanical stress.

When selecting a ceramic capacitor for a specific application, it’s important to consider factors such as required capacitance value, voltage rating, temperature stability, frequency response, and any non-ideal effects that might impact performance. The choice of ceramic capacitor type should be based on the specific requirements of the circuit and the characteristics that best match the application’s needs.

Ceramic Capacitors Advantages

They are compact and have a high capacitance-to-volume ratio, making them suitable for applications where space is limited.

They have low equivalent series resistance (ESR) and equivalent series inductance (ESL), which makes them suitable for high-frequency applications.

Ceramic capacitors are generally more stable across temperature ranges compared to electrolytic capacitors.

Ceramic Capacitors Disadvantages

They might exhibit non-linear behavior, voltage dependency, and microphonic effects (piezoelectric properties) under certain conditions.

The capacitance of ceramic capacitors can vary with voltage, temperature, and aging, which might impact their performance in precision applications.

Electrolytic Capacitors

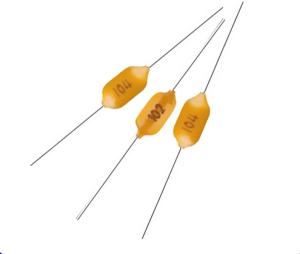

Electrolytic capacitors are a type of capacitor that uses an electrolyte (usually a liquid or gel-like substance) as one of its plates, allowing for higher capacitance values compared to other types of capacitors. They are widely used in electronic circuits, particularly in applications where larger capacitance values are needed, such as in power supply filtering, audio amplifiers, and DC blocking.

Here are some key features and characteristics of electrolytic capacitors:

- Capacitance Range: Electrolytic capacitors typically offer higher capacitance values than other types of capacitors, ranging from microfarads (µF) to thousands of microfarads, making them suitable for applications requiring larger energy storage.

- Polarity: Most electrolytic capacitors are polarized, meaning they have a positive and a negative terminal. It’s important to observe proper polarity during installation to prevent damage or failure.

- Construction: Electrolytic capacitors consist of two electrodes separated by an electrolyte-soaked material. The electrolyte provides a larger effective plate area, enabling higher capacitance values in a relatively compact package.

- Voltage Rating: Electrolytic capacitors are available with varying voltage ratings, from a few volts to several hundred volts or more, making them suitable for a wide range of voltage levels.

- Size and Form Factors: They come in various sizes and package types, including radial, axial, and surface-mount, allowing for flexibility in design and installation.

- Low ESR: Electrolytic capacitors typically exhibit higher equivalent series resistance (ESR) compared to ceramic capacitors, but their ESR can be relatively low in the case of solid aluminum electrolytic capacitors.

- Temperature Stability: Electrolytic capacitors might have limited temperature stability compared to some other capacitor types. High temperatures can lead to a decrease in capacitance and an increase in equivalent series resistance (ESR).

- Lifetime and Aging: Electrolytic capacitors have a limited lifetime due to factors such as electrolyte drying, which can occur over time and lead to changes in capacitance and ESR. This aging process might impact their performance and reliability.

- High Ripple Current Handling: Due to their higher capacitance and often lower ESR, electrolytic capacitors are well-suited for applications where they need to handle higher ripple currents in power supply filtering.

- Cautions: When using electrolytic capacitors, especially aluminum electrolytic capacitors, designers need to consider factors such as temperature, voltage derating, and application-specific requirements to ensure proper performance and longevity.

When selecting an electrolytic capacitor for a specific application, engineers need to consider factors such as required capacitance, voltage rating, size constraints, temperature range, ESR, expected lifetime, and ripple current handling capability. Electrolytic capacitors are particularly useful in applications where their unique combination of capacitance and size makes them the most appropriate choice for energy storage and filtering needs.

Electrolytic Capacitors Advantages

They are available in larger capacitance values compared to ceramic capacitors, which makes them suitable for applications requiring higher energy storage.

Electrolytic capacitors are often used in power supply and audio applications where their relatively higher ESR can help with filtering and energy dissipation.

They tend to be more cost-effective for high capacitance values.

Electrolytic Capacitors Disadvantages

Electrolytic capacitors are larger and have a lower capacitance-to-volume ratio compared to ceramics.

They may not be as stable across temperature ranges and could exhibit higher temperature-dependent behavior.

Over time, electrolytic capacitors can experience electrolyte drying, which can lead to a decrease in capacitance and an increase in ESR.

In summary, neither ceramic capacitors nor electrolytic capacitors are universally better than the other. The choice between them depends on the specific requirements of the circuit and the application’s characteristics. Designers need to consider factors such as capacitance, voltage, frequency, size constraints, temperature stability, cost, and other performance considerations when selecting the appropriate capacitor type for their circuit. Often, a combination of capacitor types might be used in a design to take advantage of their respective strengths and mitigate their weaknesses.