Electrolytic and ceramic capacitors are two common types of capacitors used in electronic circuits for various applications. They have different characteristics and are suited for different purposes due to their unique electrical properties.

Electrolytic Capacitors

An electrolytic capacitor is a type of capacitor that uses an electrolyte (usually a liquid or gel-like substance) as one of its plates to achieve a large capacitance value in a relatively small physical size. Electrolytic capacitors are commonly used in electronic circuits for various applications due to their high capacitance and relatively low cost. Here are some key features and characteristics of electrolytic capacitors:

- Polarized: Electrolytic capacitors are polarized, meaning they have a positive (+) and a negative (-) lead. This polarization is important, as reversing the voltage polarity can damage the capacitor or even cause it to fail catastrophically.

- Dielectric: The dielectric material in electrolytic capacitors is typically a thin oxide layer that forms on the surface of one of the electrodes. This dielectric layer separates the two plates and allows for energy storage.

- Capacitance: Electrolytic capacitors can achieve high capacitance values, often in the microfarad (µF) to farad (F) range. This high capacitance makes them suitable for applications where a large amount of charge needs to be stored.

- Voltage Rating: They are available with various voltage ratings, typically ranging from a few volts to several hundred volts. The voltage rating indicates the maximum voltage the capacitor can withstand before breaking down.

- Size and Form Factor: Electrolytic capacitors come in various sizes, but they are generally larger than other types of capacitors like ceramic capacitors. They are commonly cylindrical in shape and can also be found in axial or radial lead configurations.

- Applications:

- Power Supply Filtering: Electrolytic capacitors are often used in power supply circuits to smooth out voltage fluctuations and provide energy reservoirs.

- Coupling and Blocking: They can be used for coupling audio or AC signals between stages of an amplifier or electronic circuit.

- Timing Circuits: In some cases, electrolytic capacitors are used for timing purposes in conjunction with resistors.

- Audio Applications: Due to their larger capacitance values, they are suitable for low-frequency filtering in audio circuits.

- ESR (Equivalent Series Resistance): Electrolytic capacitors have an inherent equivalent series resistance due to the properties of the electrolyte. This ESR can impact their performance, especially in high-frequency applications.

- Lifetime and Aging: Electrolytic capacitors have a finite lifespan and can degrade over time due to factors such as temperature, voltage stress, and the properties of the electrolyte. This degradation can lead to increased ESR and reduced capacitance.

When using electrolytic capacitors in your circuits, it’s essential to take their polarization, voltage ratings, ESR, and aging characteristics into consideration to ensure proper operation and reliability.

Ceramic Capacitors

Ceramic capacitors are a type of capacitor that uses ceramic materials as the dielectric to achieve energy storage. They are widely used in electronic circuits for various applications due to their small size, low cost, and range of capacitance values. Here are the key features and characteristics of ceramic capacitors:

- Dielectric Material: Ceramic capacitors use ceramic materials as the dielectric, which separates the two capacitor plates. Different types of ceramic materials result in different electrical properties, making various ceramic capacitor classes suitable for different applications.

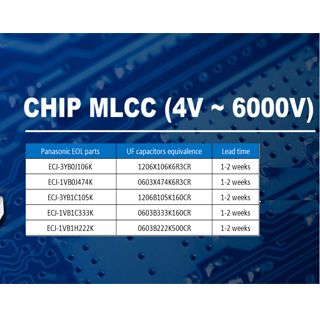

- Capacitance Range: Ceramic capacitors come in a wide range of capacitance values, spanning from picofarads (pF) to microfarads (µF), making them suitable for a variety of circuit requirements.

- Non-Polarized: Ceramic capacitors are non-polarized, meaning they don’t have a specific positive or negative lead. They can be connected in either direction in a circuit.

- Voltage Rating: The voltage ratings of ceramic capacitors can vary, ranging from a few volts to several hundred volts. The voltage rating indicates the maximum voltage the capacitor can handle without breaking down.

- Size and Form Factor: Ceramic capacitors are known for their small physical size, making them suitable for compact electronic designs. They are available in various package styles, including surface-mount and through-hole configurations.

- Dielectric Classes: Ceramic capacitors are classified into different dielectric classes based on their temperature stability, capacitance change with voltage, and other characteristics. Common classes include:

- Class 1 (C0G/NP0): These capacitors offer very stable capacitance across temperature and voltage variations. They are often used in precision applications and timing circuits.

- Class 2 (X7R, Y5V, etc.): These capacitors provide higher capacitance values but may exhibit some variation with temperature and voltage. They are often used for general-purpose decoupling and filtering.

- Applications:

- Decoupling and Bypassing: Ceramic capacitors are widely used for decoupling and bypassing purposes, where they provide a low-impedance path for high-frequency noise to ground.

- High-Frequency Filtering: Due to their small size and fast response, ceramic capacitors are suitable for high-frequency filtering in RF and digital circuits.

- Timing and Oscillation: Certain ceramic capacitor types, especially those with stable characteristics, are used in timing circuits and oscillator circuits.

- General-Purpose Applications: Ceramic capacitors are commonly used in a wide range of electronic applications where their compact size and low cost are advantageous.

- Temperature Stability: The temperature stability of ceramic capacitors can vary depending on the dielectric class. Class 1 capacitors like C0G/NP0 have excellent stability, while Class 2 capacitors like X7R and Y5V exhibit more variation with temperature.

It’s important to choose the appropriate class of ceramic capacitor for your application based on factors like required capacitance value, temperature stability, and voltage requirements. Keep in mind that Class 1 capacitors are better suited for applications that demand precise and stable capacitance values, while Class 2 capacitors are suitable for general-purpose applications where tighter stability is not critical.

Learn more:Are ceramic capacitors better than electrolytic?

In summary, the choice between electrolytic and ceramic capacitors depends on the specific requirements of your electronic circuit. If you need high capacitance values and higher voltage ratings, electrolytic capacitors might be more appropriate. On the other hand, if you’re dealing with high-frequency applications, noise suppression, or need compact components, ceramic capacitors could be a better choice. It’s essential to consider factors like voltage, capacitance, frequency range, and physical space when selecting the appropriate capacitor for your circuit.