The main differences between tantalum capacitors and “normal” capacitors (which usually refer to ceramic capacitors or aluminum electrolytic capacitors) lie in their construction, characteristics, and applications. Here’s a comparison of these capacitor types.

Construction and Dielectric Material

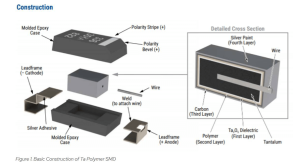

- Tantalum Capacitors: Tantalum capacitors use tantalum metal for both the anode and cathode. The dielectric material is tantalum pentoxide (Ta2O5), which forms a thin insulating layer on the tantalum anode. This construction allows for high capacitance in a compact form.

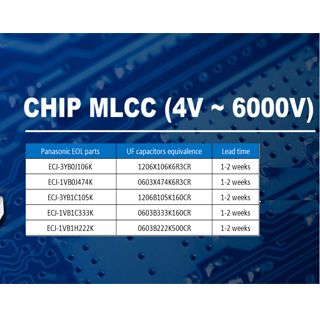

- Ceramic Capacitors: Ceramic capacitors use a ceramic material as the dielectric. The electrode material can be ceramic or metal. They are available in various dielectric types, such as Class 1 (high stability, low capacitance tolerance) and Class 2 (higher capacitance but less stable).

- Aluminum Electrolytic Capacitors: Aluminum electrolytic capacitors use an aluminum anode, an electrolytic solution, and an oxide layer as the dielectric. These capacitors tend to be larger in size compared to tantalum capacitors.

Capacitance and Size

- Tantalum capacitors offer relatively high capacitance values per unit volume, making them suitable for compact designs where high capacitance is needed.

- Ceramic capacitors are available in a wide range of capacitance values but generally have lower capacitance compared to tantalum capacitors of similar size.

- Aluminum electrolytic capacitors have moderate to high capacitance values but tend to be larger in physical size compared to tantalum capacitors.

Voltage Ratings

- Tantalum capacitors and ceramic capacitors have a wide range of voltage ratings to suit different applications.

- Aluminum electrolytic capacitors are often used for higher voltage applications.

Polarity

- Tantalum capacitors are polarized, meaning they have a positive and negative terminal due to their asymmetric construction.

- Ceramic capacitors are usually not polarized and can be connected in either direction.

- Aluminum electrolytic capacitors are also polarized.

ESR and Frequency Response

- Tantalum capacitors tend to have low Equivalent Series Resistance (ESR) and are suitable for applications requiring low impedance and good high-frequency characteristics.

- Ceramic capacitors generally have lower ESR and excellent high-frequency performance.

- Aluminum electrolytic capacitors typically have higher ESR and may not perform as well at high frequencies.

Applications

- Tantalum capacitors are often used in applications requiring high capacitance in a small size, such as decoupling and filtering in portable electronics.

- Ceramic capacitors are used for decoupling, filtering, timing circuits, and bypassing in a wide range of applications.

- Aluminum electrolytic capacitors are often used in power supply filtering, audio applications, and situations where higher capacitance values are required.

Discover related topics: How to identify tantalum capacitor

Each type of capacitor has its strengths and weaknesses, and the choice depends on the specific requirements of the circuit and application. It’s important to understand the characteristics of each type to make the right selection.