Motor capacitors, paper capacitors, and film capacitors are all different types of capacitors used in various electrical and electronic applications. Here’s a comparison of motor capacitors, paper capacitors, and film capacitors.

Motor Capacitors

Motor capacitors are specifically designed for use in electric motors. They are used to improve the motor’s power factor and efficiency. Motor capacitors are often electrolytic capacitors, which are known for their relatively high capacitance values and ability to handle high voltages. They are generally used in AC induction motors to help improve the motor’s starting torque and overall efficiency.

Purpose: Motor capacitors are primarily used to improve the power factor and starting torque of electric motors. They help motors run more efficiently and with better performance.

Types: There are two main types of motor capacitors: start capacitors and run capacitors.

Start Capacitors: These capacitors are used to provide an extra boost of power during the starting phase of a motor. They are connected in series with the motor’s start winding and are typically disconnected from the circuit once the motor reaches its operating speed.

Run Capacitors: These capacitors are designed to remain connected to the motor circuit at all times, providing improved efficiency and power factor during the motor’s operation.

Capacitance and Voltage Ratings: Motor capacitors come in various capacitance values and voltage ratings to suit different motor sizes and applications.

Types of Dielectric: The dielectric material used in motor capacitors can vary. Common dielectric materials include film (polypropylene, polyester), electrolytic, and ceramic.

Mounting: Motor capacitors are often designed for easy mounting within motor enclosures or control panels.

Usage: They are commonly used in single-phase and three-phase induction motors found in various applications, such as air conditioning units, refrigerators, washing machines, pumps, fans, and more.

Replacement: If a motor capacitor fails, it can lead to reduced motor performance, overheating, or motor failure. It’s important to replace faulty capacitors promptly to ensure the motor’s proper functioning.

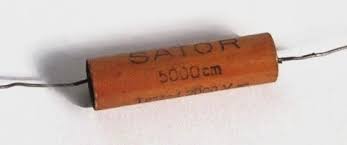

Paper Capacitors

Paper capacitors, also known as paper dielectric capacitors, were common in earlier electronic devices. They used layers of paper as the dielectric material between the capacitor plates. However, paper capacitors have largely been replaced by more modern and reliable capacitor technologies. Paper capacitors had limitations such as susceptibility to moisture, aging, and limited temperature stability.

Dielectric Material: The dielectric material in paper capacitors was typically made of layers of paper that were impregnated with an insulating oil. The oil-soaked paper acted as the dielectric between the capacitor’s plates.

Construction: Paper capacitors were constructed by winding layers of the oil-impregnated paper and metal foil to create the capacitor’s structure.

Applications: Paper capacitors were used in various electronic circuits and devices, including radios, televisions, and other early electronic equipment.

Limitations: While paper capacitors were widely used in their time, they had several limitations. They were susceptible to aging, moisture absorption, and changes in capacitance value over time. These factors could lead to performance degradation and circuit malfunctions.

Obsolete Technology: With advancements in capacitor technology, paper capacitors have largely become obsolete. Modern capacitors, such as film capacitors and ceramic capacitors, offer better reliability, stability, and performance.

Replacement: Many vintage electronics that originally used paper capacitors may require replacement or restoration as these capacitors can deteriorate over time, affecting the functionality of the equipment. When restoring older electronics, replacing paper capacitors with modern equivalents is often recommended.

Film Capacitors

Film capacitors are a type of capacitor that use a thin plastic film as the dielectric material. They come in various types, including polyester (PET), polypropylene (PP), polycarbonate (PC), and others. Film capacitors offer good stability, reliability, and temperature performance. They are often used in applications requiring high voltage and high-frequency characteristics, such as power electronics, audio equipment, and signal processing.

Application: Film capacitors have a wider range of applications beyond just electric motors, including power electronics, audio equipment, signal processing, and more.

Function: Film capacitors are used to store and release electrical energy, filter signals, and stabilize voltage levels.

Types: Film capacitors come in various types, such as polyester (PET), polypropylene (PP), and others, each with specific characteristics suited to different applications.

Dielectric Material: Film capacitors always use a thin plastic film as the dielectric material.

Voltage Rating: Film capacitors come in a variety of voltage ratings, making them suitable for a broad range of applications.

Mounting: They are available in different package styles, suitable for various mounting options.

Usage: Film capacitors are used in a wide range of electronic and electrical circuits, including filtering, coupling, decoupling, timing, and more.

In summary

While both motor capacitors and film capacitors are capacitive devices, they serve different purposes and are designed for distinct applications. Motor capacitors are tailored for improving motor performance, while film capacitors have a broader application scope across electronics and electrical engineering.