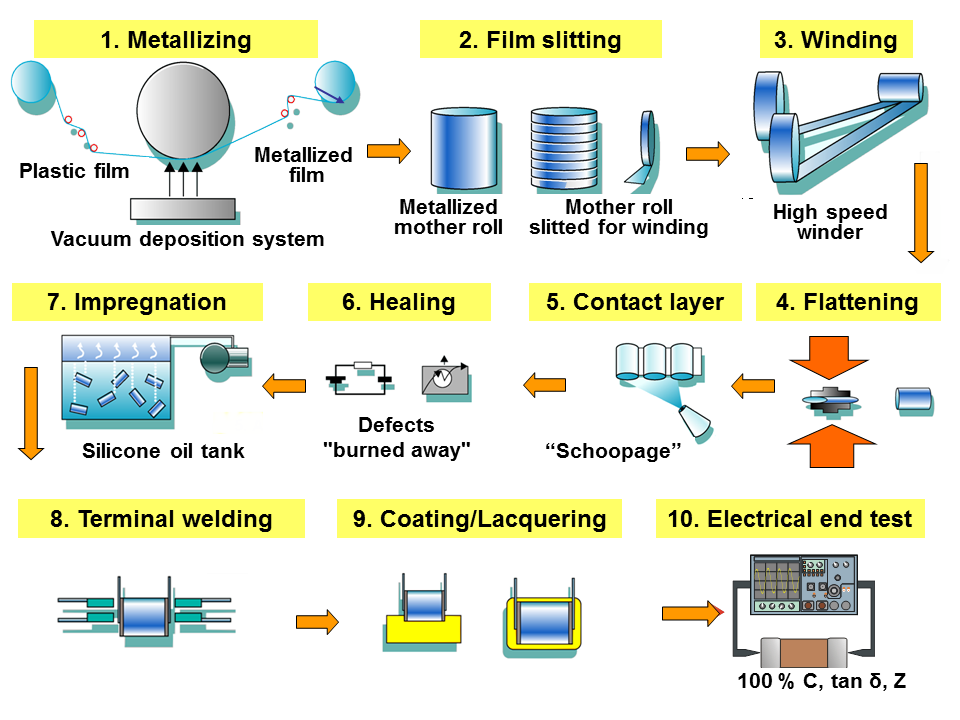

Construction

A power film capacitor, also known as a power film capacitor or a power film metallized capacitor, is a type of capacitor specifically designed to handle high power levels and provide reliable energy storage and voltage regulation in electronic and electrical circuits. These capacitors are often used in applications where high-power handling capabilities, low equivalent series resistance (ESR), and high reliability are essential.

Discover related topics: What is a power film capacitor

Key characteristics and features

- Dielectric Material: Power film capacitors typically use a high-quality, self-healing polypropylene film as the dielectric material. This dielectric material can withstand high voltage levels and is known for its stability over time.

- Metallized Electrodes: The electrodes of power film capacitors consist of a thin metal film that is vacuum-deposited onto the dielectric material. This metallization process provides a large surface area for energy storage and efficient power handling.

- High Voltage Ratings: Power film capacitors are designed to handle high voltage levels, making them suitable for applications where voltage regulation and energy storage are critical. They can operate at voltage ratings ranging from hundreds of volts to several kilovolts.

- High Power Density: These capacitors have a high power density, meaning they can store and discharge energy quickly without overheating. This makes them ideal for applications with rapid energy requirements.

- Low ESR and ESL: Power film capacitors have low Equivalent Series Resistance (ESR) and Equivalent Series Inductance (ESL). This low ESR and ESL contribute to their excellent high-frequency characteristics and ability to filter out noise and ripple in power circuits.

- High Reliability: Power film capacitors are known for their high reliability and long operational life. They can withstand harsh environmental conditions and maintain their electrical characteristics over time.

- Wide Temperature Range: These capacitors are often capable of operating over a wide temperature range, which makes them suitable for use in extreme environmental conditions.

Film capacitors be used in AC

Film capacitors can be used in AC (alternating current) circuits. Film capacitors are versatile and can be employed in both AC and DC (direct current) applications. However, there are a few considerations to keep in mind when using film capacitors in AC circuits:

- Voltage Rating: Ensure that the film capacitor’s voltage rating is suitable for the AC voltage in the circuit. AC voltage is typically expressed in terms of RMS (Root Mean Square) voltage, which is lower than the peak voltage. Select a capacitor with a voltage rating that comfortably exceeds the RMS voltage to ensure safe operation.

- Capacitance Value: Choose a film capacitor with the appropriate capacitance value for the specific AC application. The capacitance value determines the ability of the capacitor to store and release energy in the AC circuit.

- Frequency Response: Consider the frequency of the AC signal. Film capacitors are known for their relatively stable capacitance values over a wide frequency range. However, for very high-frequency AC applications, you may need specialized film capacitors designed for such frequencies.

- Temperature Range: Ensure that the chosen film capacitor can operate within the temperature range of your AC circuit. Film capacitors are available in various temperature ratings, so select one that matches the environmental conditions of your application.

- Dielectric Type: Different types of film capacitors use different dielectric materials, such as polypropylene, polyester, or others. The choice of dielectric material can impact the capacitor’s performance in AC applications, so select the appropriate type based on your needs.

- Series or Parallel Configuration: Depending on the AC circuit and its requirements, you may need to connect film capacitors in series or parallel to achieve the desired capacitance and voltage ratings. Ensure that the connections are made correctly.

- Safety Considerations: Film capacitors, like any capacitors, can store electrical energy. Take appropriate safety precautions when working with high-voltage AC circuits to avoid electrical shock hazards.

Film capacitors are commonly used in AC applications for purposes such as power factor correction, AC filtering, motor run capacitors, and more. They are valued for their reliability, low ESR (Equivalent Series Resistance), and good performance over a wide frequency range, making them suitable for various AC circuit designs. However, as with any component selection, it’s essential to choose the right film capacitor based on the specific requirements of your AC circuit.