NTC Thermistor 10k Introduction

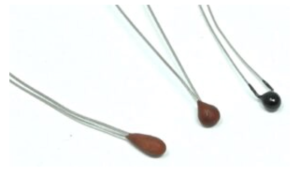

In the realm of temperature sensing and compensation, the NTC thermistor 10k (Negative Temperature Coefficient thermistor with a nominal resistance of 10,000 ohms) emerges as a remarkable and indispensable device. Its ability to exhibit a decline in resistance as temperature rises has found applications in a plethora of industries, from consumer electronics to automotive systems. This essay delves into the parameters, characteristics, applications, and significance of the NTC Thermistor 10k.

What Parameters of NTC thermistors 10K

At its core, the NTC Thermistor 10k boasts a nominal resistance of 10,000 ohms at a designated reference temperature, often set at 25°C. This resistance-temperature relationship follows a nonlinear trajectory, often described by equations such as the Steinhart-Hart equation. The thermistor’s sensitivity to temperature variations and its rapid response to changes enable it to capture even the subtlest temperature shifts with precision. A key parameter, the Beta (β) value, defines the curve’s shape and offers insight into the thermistor’s sensitivity, enhancing its suitability for specific applications.

- Nominal Resistance (R25): The thermistor’s nominal resistance is 10,000 ohms at a specific reference temperature, often 25°C (R25 = 10,000 ohms).

- Resistance-Temperature Curve: NTC thermistors exhibit a nonlinear resistance-temperature relationship. As the temperature increases, the resistance decreases, following an exponential curve. The specific equation that describes this relationship can vary based on the thermistor’s construction and material.

- Beta (β) Value: The β value, also known as the B-value or Beta coefficient, is a parameter used to describe the shape of the resistance-temperature curve. It is often used to approximate the thermistor’s behavior over a limited temperature range. The β value helps define the sensitivity of the thermistor to temperature changes.

- Operating Temperature Range: NTC thermistors can operate across a certain temperature range, which depends on the specific thermistor’s design and material properties. This range may extend from sub-zero temperatures to a specific maximum temperature.

- Accuracy: The accuracy of a temperature measurement using an NTC thermistor depends on factors like the accuracy of the thermistor’s resistance-temperature curve, the quality of manufacturing, and the calibration applied. Careful consideration of these factors is important for accurate temperature sensing.

- Tolerance: The tolerance of the nominal resistance value specifies the allowable variation from the nominal value at the reference temperature. Common tolerance levels are ±1%, ±2%, ±5%, and ±10%.

- Response Time: NTC thermistors have relatively fast response times due to their high sensitivity to temperature changes. The response time is the time it takes for the thermistor’s resistance to stabilize after a temperature change.

- Self-Heating: NTC thermistors generate heat when current flows through them, leading to self-heating effects. This effect can impact accuracy, especially in applications where the thermistor’s current is significant.

- Circuit Configuration: NTC thermistors are often used in voltage divider circuits, where the thermistor is in series with a resistor. This forms a voltage divider that produces a varying output voltage proportional to the thermistor’s resistance change with temperature.

- Calibration and Compensation: Due to their nonlinear behavior, NTC thermistors may require calibration or compensation techniques to achieve accurate temperature measurements across a wide range of temperatures.

Diverse Applications

The applications of the NTC Thermistor 10k are as diverse as they are significant. In the automotive sector, these thermistors find their place in coolant temperature sensing, contributing to engine efficiency and performance. In household appliances, they assist in regulating temperatures in ovens and HVAC systems, ensuring comfort and safety. Moreover, medical devices, industrial processes, and consumer electronics leverage these thermistors to maintain optimal operating conditions and prevent overheating.

Precision and Calibration

While the NTC Thermistor 10k offers remarkable accuracy within its designated temperature range, its nonlinear resistance-temperature relationship demands careful calibration or compensation to ensure precise measurements across varying temperatures. Factors like tolerance levels, response time, and self-heating effects need consideration when designing circuits for optimal accuracy.

Circuit Integration and Design

The NTC Thermistor 10k’s simplicity in circuit integration is a notable advantage. Often configured within voltage divider circuits, these devices create a voltage output proportional to their changing resistance. This output voltage, in turn, can be measured and correlated to temperature, facilitating seamless integration into various electronic designs.

Advantages and Considerations

The NTC Thermistor 10k’s virtues are abundant. Its cost-effectiveness compared to other temperature sensors like RTDs and thermocouples, coupled with its compact size and high sensitivity, makes it an attractive choice across industries. However, it’s crucial to recognize that while NTC thermistors excel in their designed temperature range, they might not be suitable for extreme environments or applications requiring utmost linearity.

Conclusion

In the world of temperature sensing, the NTC Thermistor 10k stands as a true marvel, bridging the gap between accurate measurements and practical implementation. Its sensitivity, nonlinear behavior, and cost-effectiveness make it an invaluable asset in countless applications, from automotive systems to household gadgets. As technology advances, it’s certain that the NTC Thermistor 10k will continue to be a cornerstone of temperature management and regulation, impacting industries and enhancing our lives in ways both seen and unseen.